In the world of automation and robotics, the term “actuator” holds very significant importance. While it may sound like complex technical jargon to the non-technical, actuators are at the heart of countless systems that involve physical movement and control by converting energy. In simple terms, it is a mechanical device in any machine that initiates movement often by an Electrical actuator, Air (Pneumatic actuator) or hydraulic actuator.

We are surrounded by countless examples whether it’s the graceful motion of a robotic arm, the precision of a 3D printer, or the responsive adjustments of an aircraft wing, actuators play a vital role in making these actions possible. In this article, we will briefly discuss what an actuator is, actuator types, actuator applications & how to select an actuator. So, let’s embark on this exciting journey of discovery and unveil the power behind dynamic motion.

What is an actuator?

So, what is an actuator? An actuator is simply a device that receives energy as input and converts it into motion or force. Basically, an Actuator needs a control signal and source of energy to initiate the mechanical motion. By applying force, torque, or displacement, actuators enable machines to perform an array of tasks with accuracy and efficiency.

Actuators are utilized in a broad spectrum of industries, ranging from gas turbines to operating valves & cylinders in industrial plants to aerospace and automotive industries to manufacturing and healthcare.

What are the different types of actuators used? Actuators are classified as per the type of motion they produce and the type of power or source of energy they use to control the movement.

Types of actuator

Actuator types vary based on motions, power configurations, styles and sizes depending on the application. The type of actuator is classified as Based on Motion & Based on Source of Energy. In detail information about both types of actuators is explained as below:

Based on Motion

Actuators that are based on motion create two main types of motions – Linear & Rotary.

Linear Actuators:

Linear actuators are designed to generate linear motion or movement. Unlike rotary actuators that produce rotational motion, linear actuators are specifically designed to move objects or components along a straight line. It primarily uses a belt, pulley, rack and pinion or ball screw to convert electric motor rotation into linear motion.

By doing so, Linear actuators can push, pull, lift, lower, or position objects with precision and control. They are widely used in various industries, including manufacturing, robotics, food processing, aerospace, automobiles, medical industries, material handling and many other applications that require push, pull, lifting & positioning.

There are several types of linear actuators each using different mechanisms to achieve linear motion. Here are a few examples:

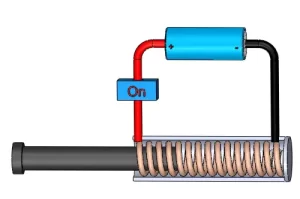

Electric Linear Actuators: These actuators use an electric motor coupled with a screw or a belt mechanism, to convert rotary motion into linear motion. Electric linear actuators are known for their precise control, ease of use, and versatility. They can be found in applications such as robotics, Belt conveyer system, material handling automation systems, adjustable furniture, and home appliances like sliding gates, and doors.

Hydraulic Linear Actuators: Hydraulic actuators uses fluid pressure to generate linear motion. It consists of a piston connected to a rod within a cylinder. When hydraulic fluid is pumped into the cylinder, it applies pressure to the piston, causing the rod to extend or retract. Hydraulic actuators are capable of providing high-force output and are commonly used in heavy-duty applications such as construction equipment, industrial machinery, and automotive systems.

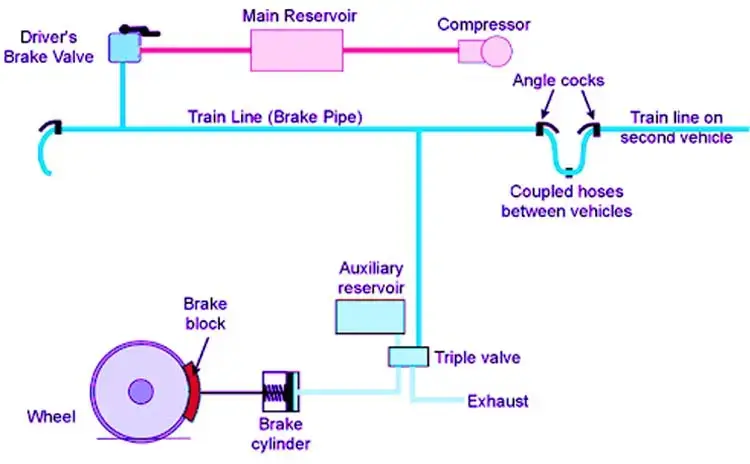

Pneumatic Linear Actuators: Pneumatic actuators utilize compressed air or gas to generate linear motion. They work on similar principles to hydraulic actuators, but instead of hydraulic fluid, it uses compressed air to create pressure and movement. Pneumatic actuators are widely used because of their simplicity, rapid response times, and suitability for clean environments. They are often employed in industries such as packaging, assembly lines, and pneumatic systems.

Linear actuators can be controlled manually or through automated systems. In manual control, a user operates switches, buttons, or levers to initiate the actuator’s movement. In automated control, sensors, feedback systems, and programmable logic controllers (PLCs) are used to monitor and regulate the actuator’s position, speed, and force. This allows for precise and repeatable motion control in complex systems.

Rotary actuators:

As the name rotary actuators, they convert energy into rotary motion by using a shaft to control equipment speed, position & rotation. One of the most common examples of rotary actuators is Electrical motors powered by an electric signal.

They produce high torque and hence Rotary actuators are used for various industrial applications such as Clamping, Transferring parts, Positioning, robotics, radar, flight simulators, the semiconductor industry, special machine manufacturing & defence industry. Rotary actuators come in various types each with its own unique characteristics and applications.

Based on the Source of Energy

The working principle of Rotary actuators depends upon the type of transformation applied such as pneumatic, hydraulic or electrical energy to achieve mechanical rotation. Based on the source of energy applied they are further classified as Pneumatic Actuator, Electrical Actuator, Hydraulic Actuator, Magnetic & Thermal Actuator.

Pneumatic Actuators

In the Pneumatic actuator, the pressure is applied through compressed air or compressor to generate oscillatory rotary motion. There are two most common configurations for Pneumatic Rotary actuators known as – Rac & Pinion configuration and Vane configuration.

Rack and pinion actuators comprise of Piston and rack that creates movement in a linear fashion and cause the pinion gear and output shaft to rotate. Rack and pinion actuators can comprise single, double or even multiple racks while a vane is configured or mounted on a central shaft enclosed in a cylindrical casing. The vane rotates upon receiving pressure and continues to rotate until it reached the end of strokes. Air pressure applied to another side of the vane causes it to rotate the shaft in the opposite direction. The main advantage of using a Pneumatic rotary actuator is its simplicity, durability, high force output and its ability to be used in hazardous areas.

Hydraulic Actuators

The Hydraulic rotary actuators use a hydraulic fluid in order to develop pressure to generate rotational motion. They are known for their high force output and are commonly used in heavy-duty applications. Key features of hydraulic rotary actuators include:

Piston-based actuators: These actuators consist of a piston connected to the output shaft encased within a cylinder. The Pressurized hydraulic fluid enters the cylinder, creating a force on the piston and causing rotational motion. Piston-based hydraulic rotary actuators provide high torque and are suitable for applications requiring substantial force, such as construction equipment and industrial machinery.

Electric Actuators

Electric actuators use electric motors to generate rotary motion. Electric actuators deliver precise control, and high efficiency, and can be easily integrated into an automated system. Electric Actuators can be operated by AC or DC motors and are most commonly used in applications that require precise control, low noise, and low maintenance. The Electric actuators can be designed within electric actuators, including:

Gear-driven actuators: The Gear driven actuators make use of gears to transmit torque from the motor to the output shaft. It provides high torque output and is suitable for applications that require heavy-duty operation and precise positioning.

Direct drive actuators: Direct drive actuators, also known as torque motors, these actuators eliminate the need for gears and they work directly by coupling the motor to the output shaft. Direct drive actuators offer exceptional precision, low backlash, and high dynamic response, making them ideal for applications that demand high accuracy and quick movements.

Each type of rotary actuator offers distinct advantages and is suited for specific applications based on factors such as torque requirements, speed, precision, and environmental conditions. Understanding the characteristics of each type is crucial in selecting the appropriate rotary actuator for a given application.

Electromagnetic actuators

Electromagnetic actuators are based on the Principle of Lorentz Forces, which states that the magnetic field produced by a current-carrying conductor placed in a static magnetic field interacts with the static field to produce a force. This force can be used to create the movement of a mechanical structure.

Electromagnetic Actuators are used for very specific applications such as Nano-robots and have huge potential in the field of bio-medicals. Their main advantage is that they require low voltages and require no contact operation. One more kind of Electromagnetic actuator is known as Magneto Rheological Fluid Actuator. Basically, these fluids solidify in the presence of a magnetic field and are mostly used in applications in hydrodynamic bearings, semi-active clutches, etc.

An example where Electromagnetic actuators are used are Magnetostrictive micro walkers used in biomedical applications, and magnetorheological fluid actuators are used as valves, brakes, and dampers.

Conclusion

Actuators form the backbone of modern automation, allowing machines to move with precision and perform complex tasks. From electric to hydraulic, pneumatic to mechanical, these devices come in various forms, each tailored to specific applications.

Whether it’s enhancing industrial productivity, enabling robotic advancements, or improving healthcare solutions, actuators have transformed the way we interact with technology. Understanding the power and versatility of actuators is key to unlocking the potential of automation and driving innovation across industries. So, next time you witness a seamless movement or precise adjustment, remember the unsung hero behind it all—the actuator.