Flow control is an area where many different types of valves are used. They are used for various reasons & media such as Liquid, gases, pressure, temperature, mixed contents, and so on. If we look at other types of valves in the quarter-turn family they are preferably used as open & close action mostly. But in the case of butterfly valve operation, it is the only valve that is used as a control device for many reasons or all of the above-mentioned reasons. In this article, we will learn about what is butterfly valve, Butterfly parts & their function, their advantages & disadvantages, Application of the Butterfly valve. So let’s start.

What is Butterfly valve?

The butterfly valve belongs to the quarter-turn valve family that is used for shutting the flow in a pipeline. The Butterfly valve consists of Disc which is connected to a rod.

The rod is then operated by a lever or by mounting an actuator on it. One can easily determine if the valve is open if the handle is parallel to the valve and closed in condition when it is perpendicular to the valve.

The working principle is very similar to a Ball valve.

It is often said that the Butterfly valve can be used to regulate the flow but we do not recommend doing this as this can cause damage to the disk. Due to this, it can create a negative effect on sealing properties.

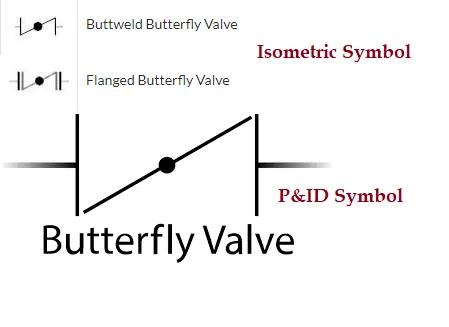

Butterfly valve symbol

Below is the symbol used to denote a butterfly valve in isometric and P&ID

Butterfly valve main parts

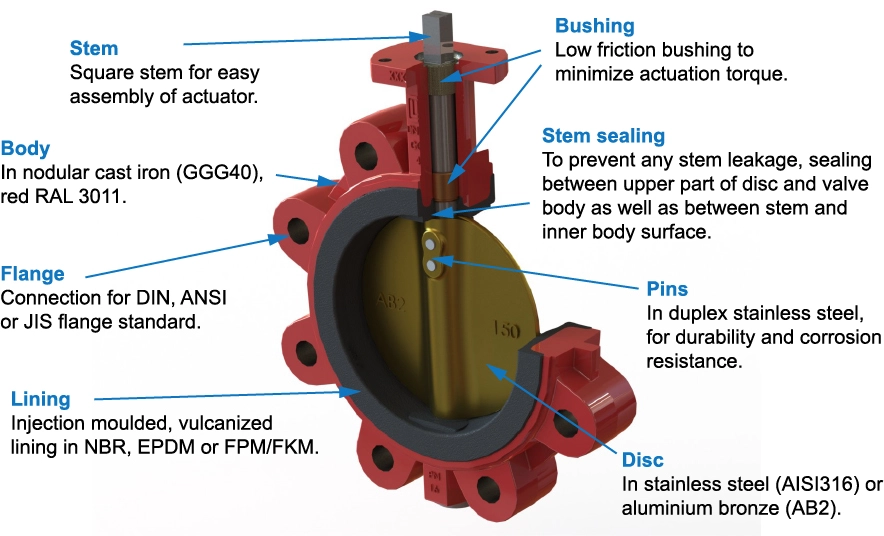

There are 4 main parts of the butterfly valve namely the Body, Disc, Stem, Seat and the other parts of the butterfly valve includes Seal, Bushing, Lining, Seat ring, and Packing gland.

The below picture demonstrates the butterfly valve parts:

Let’s go through the Butterfly valve parts in detail.

BODY

The most common body designs are Wafer type butterfly valves and Lug-type butterfly valves. These two types are sandwiched between two pipe flanges.

WAFER TYPE BUTTERFLY VALVE

Wafer-type body do not have any protruding lugs i.e., they are placed between pipe flanges, and flange bolts surrounding the body of the valve. It is very easy to install however do not consider using it as an isolation valve. The wafer-type Butterfly valves are less expensive than other types of design.

The below picture demonstrates the butterfly valve wafer type & butterfly valve lug type:

Consider Hubluxe Engineering for all your Butterfly valve requirements.

LUG TYPE BUTTERFLY VALVE

In the case of the Butterfly valve Lug type design, the valve body has protruding lugs in the periphery of the body that act as the passage to bolt holes which then match with those in the flanges.

Butterfly valve lug types are used in dead-end service that usually has a lower pressure rating. Unlike the wafer-type Butterfly valve, the lug type adds weight to the piping through the valve body.

The Wafer type Butterfly valve is usually less expensive than lug type butterfly valve, hence it is widely used.

DISC

The disc is positioned inside the body of the butterfly valve. The butterfly valve disc is one of the main components responsible for the flow of the fluid.

It works similarly to the gates or balls that are positioned inside the gate valves & ball valves.

The disc has two types: Eccentric and Concentric.

It is very easy to choose the butterfly valve as eccentric or concentric based on the real system condition. However, there can be many variations in disc design, orientation, and material in order to improve flow, sealing, and or operating torque in the application.

STEM

Though the stem is a very small component when compared with other parts of the Butterfly valve but it’s very crucial in the functioning of the valve.

Due to the stem, the valve closing and opening take place. The design is in such a way that the stem of the butterfly valve is used to connect the disc inside the valve to the handle which is positioned on the outside of the valve.

The stem may be a one-piece shaft or a two-piece shaft (also known as Split-stem) design.

It is often referred to as a shaft that supports the valve actuation mechanism and transmits the torque through itself.

In high-performance butterfly valve design, the stems are in direct contact with the media while in resilient seated designs the stems are protected from media.

SEATS

Seats are located at multiple locations within the valve to establish a tight shutoff. The seat may be pressed, bonded, or locked into the body.

They are usually made up of polymers or elastomers of various grades. The use of polymers provides the leakproof ability of the seal between the seat and the disk.

The seat materials are available in PTFE, EPDM, BUNA-N (B), and VITON.

The most common seat material is PTFE (Polytetrafluoroethylene) or reinforced RPTFE / RTFE seat is a popular choice amongst the buyer.

PTFE seat is also most commonly known as Teflon and it is characterized by its low friction, chemical resistance & fire-resistance quality. The temperature sustainability is higher amongst the PTFE seat.

A high-performance butterfly valve is offered in metal seats that allow a butterfly valve to be used even in high temperatures like 1000 deg. or 1832 F.

Types of the butterfly valve

A butterfly valve can be classified based on multiple parameters. The most common methods of selecting the valve are enlisted as below:

- Based on types of the end connection

- Wafer type

- Semi-Lug type

- Full lug type

- Double flange

- Based on types of disc design

- Concentric butterfly valve

- Eccentric butterfly valve

- Single-offset

- Double offset

- Triple offset

- Based on Seat material types

- Soft seated

- Metal Seated

- Based on the actuation method

- Manual operated butterfly valves

- Lever operated

- Gear operated

- Automated actuation

- Electric

- Pneumatic

- Hydraulic

- Manual operated butterfly valves

Based on types of the end connection

As per the piping connection type they are classified as wafer type butterfly valve, Semi lug type Butterfly valve, Lug type butterfly valve, double flange butterfly valve.

Let’s look at each one of them in detail.

a. Wafer type

Wafer type butterfly valve is sandwiched between the pipe flanges with bolts surrounding the valve body. While installing this valve, long bolts are used covering both flanges and the valve body.

Since a wafer type of butterfly valve offers good sealing against the bi-directional pressure difference in the fluid flow, it is still one of the most economical choice of the user. Wafer type butterfly valves protect against a tight seal and two-way pressure difference in the piping or wherever they are used.

This type of valve is very economical & easy to install but it should not be used as an isolation, pipe end, or at end of line service.

b. Semi Lug type

Semi lug butterfly valve is similar to the Wafer type only. In the semi-lug type, the valve body has threaded bolt holes in the top and bottom of the body.

c. Full lug type

Full lug or Lug-type butterfly valve has protruding lugs that have equidistance holes around the body which lines up in flanges in the pipeline. It has threaded metal bolts around the body and is primarily used to connect and detach the piping system.

A lug-type butterfly valve may have lower bolt torque due to the lugs that are made up of lower-strength body materials.

d. Double flange type

As the name suggests, it has two flanges on both sides i.e. on the inlet & outlet of the valve. A double flange type butterfly valve is installed between two pipes as they have elevated or winged edges in the enclosure.

This type of valve is used to regulate, control & throttle the flow. It is mostly used for dead-end service due to its resilient seated valve design.

A double-flange butterfly valve can be challenging to install in the pipeline but mechanically it is much stronger in construction than a lug or wafer design.

It is most suitable for applications that require large flow handling or high pressure. They can be operated either manually or through actuators depending on the valve sizes.

Welded type

The welded-type butterfly valves are directly welded to the pipe and are used for high-pressure services. They are rarely used for such applications, if it is even used they are installed with plastic-lined valves.

Such type of valve is typically only compatible with PN 10 / PN16 or 150# flanges. Due to this reason, components of these valves are often constructed in Bronze, aluminum, or stainless steel.

Based on types of design

- Concentric

- Eccentric

- Single offset butterfly valve

- Double offset butterfly valve

- Triple offset butterfly valve

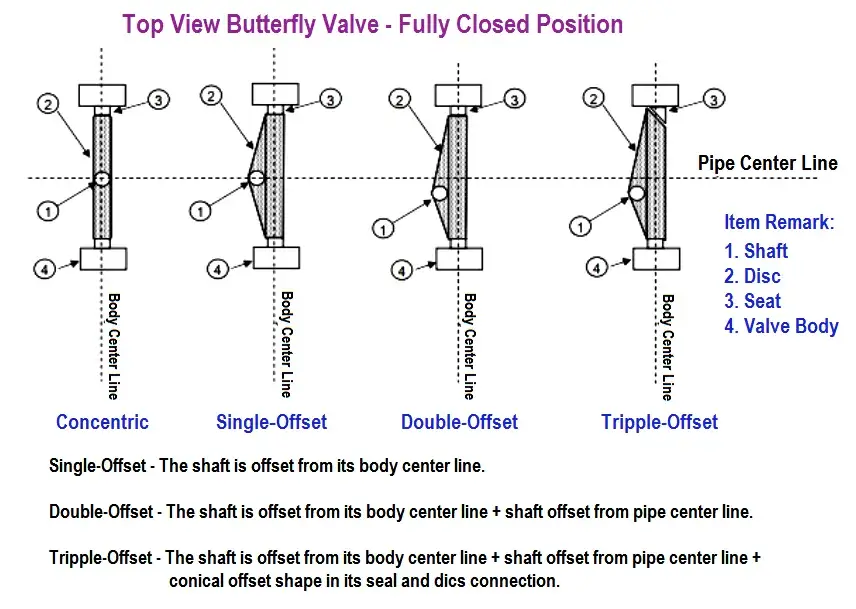

A butterfly valve can be designed to manufacture based on parameters and applications such as –Concentric (also known as Centric) and Eccentric (Single eccentric, Double eccentric & triple eccentric).

The eccentric disc has one or more stub shafts (stems) that run behind the centreline of the disc and are located in an offset position from the center of the valve. Single-offset, double-offset, and triple-offset butterfly valve is a classic examples of eccentric disc types. These types of discs are used to handle the pressure of more than PN100 or 600 LB.

Let’s go through each one of them in detail.

Concentric design: Concentric design is one of the most basic types of butterfly valve design. It is also known zero-offset valve.

It has a Concentric disc also known as a centric disc – which contains a stem that passes through the centreline of the disc. The disc of the concentric butterfly valve is simple while the eccentric butterfly valve disc comprises the disc, seal, seal holding ring, and holding bolt.

The concentric disc is designed to work for pressure suitable to 150# or PN25. They are used for low-pressure applications.

Eccentric design: The eccentric design has one or more stub shafts (stems) that run behind the centreline of the disc and are located in an offset position from the center of the valve.

These types of discs are used to handle the pressure of more than PN100 or 600 LB.

- Single-offset

- Double-offset

- Triple-offset

a. Single offset butterfly valve: A single offset valve is a butterfly valve in which the stem is located just behind the centreline of the disc.

b. Double offset butterfly valve: The double-offset butterfly valve consists of 2 offsets as compared to the concentric butterfly valve. The first offset is located slightly behind the disc while the second offset is located slightly right side of the center line. In this type, the valve body center line & disc center line both move apart.

Due to this a cam motion is generated that elevates the seal’s seat during movement. A little friction is caused during the first few degrees of opening & closing, this makes the double offset opening & closing smooth.

In this configuration, the seat will experience less friction than the concentric butterfly valve thus extending its lifespan.

Double offset is primarily used for applications where class 600# is required. Nowadays it is widely used due to its design & features which is an improved superior version of a single offset butterfly valve.

c. Triple offset butterfly valve: Triple offset as the name says, it has got 3 offsets. Just like double offset the third offset is in between the disc and seat contact axis. Due to this, there is minimal seat contact hence lifespan is comparatively very high than double offset and single offset.

Triple offset is primarily used for critical applications and is intended to work for high-pressure & high-temperature applications.

The seating arrangement in triple offset is metal-to-metal seating, which provides 100% leak-proof shutoff.

A triple offset butterfly valve is designed to work with pressure ratings of ANSI 300#, 600# & 900#. It is also used for Cryogenic to Fire safe applications.

Based on Seat material types

If we classify the butterfly valve based on the seat material types they are available as: soft seats & metal seats.

Soft seated butterfly valve: In Soft seated butterfly valves, the seals are made up of metal while the other side is made up of non-metallic. The soft seal seat comprises a certain strength, hardness, and temperature resistance. The material used in soft seated butterfly valves is EPDM, Viton, PTFE, and RPTFE.

Metal seated Butterfly valve: In metal seated butterfly valves, seals of both sides of valves are made up of metals. Materials used in metal seated varies depending on temperature and pressure and typically include Cast iron, carbon steel, stainless steel, copper, alloy steel, etc. That’s why they are used in industries that have extreme pressure and temperatures.

Based on the actuation method

The type of operation for each type of butterfly valve makes them distinguishable from each other. They are broadly categorized as Manual operated and automated actuation types.

- Manual-operated butterfly valves

- Lever operated

- Gear operated

- Automated actuation

- Electric

- Pneumatic

- Hydraulic

Lever-operated butterfly valve uses a quarter-turn lever: All lever-operated butterfly valves are quarter turn usually with a locking mechanism to open and close the disc of the valve.

It is one of the simplest types of butterfly valves but in case of large size, the lever operation is quite difficult.

Gear-operated butterfly valve: In gear operated butterfly valve a hand-operated wheel rotates the gear which is attached to the stem to move the disc. Unusually gear type butterfly valve is suitable for both small & large size butterfly valves.

Usually, manufacturers offer Gear-operated butterfly valves from the size 150 mm onwards.

Butterfly valve standards

The following are listed standards worldwide to manufacture Butterfly valves:

- API 609

- MSS SP-67

- BS EN 593

- ISO 5752

- MSS SP-68

- AWWA C504

Working Principle of the butterfly valve

The working principle is simple & the butterfly valve works on the principle of quick shutoff. The body of the valve is installed between pipes to allow movement by lever, Gear, or actuator.

With the help of the lever, gear, or actuator the opening & closing of the butterfly are performed.

The Butterfly valve provides bi-directional flow and shutoff capabilities but since they are not full bore they are not suitable for pigging or swabbing.

They are called as quarter turn valves and are popular for on-off modulating services.

Butterfly valve application

Butterfly valve applications have many areas to be used. The following enlists the butterfly valve application in major industries:

- Water supply

- Wastewater treatment

- Fire protection

- Oil & Gas

- Chemical and Pharma industries

- Fuel handling systems

- Power generation industry

- Iron ore & Steel

- Food processing

- Sugar Industries

- High-pressure and high-temperature water and steam services.

- Compressed air or gas applications.

Conclusion

I hope the concept of what is a butterfly valve, its types, the working principle, and major butterfly valve applications are clear. If you have any questions you can just comment below, and our expert will answer your queries. Kindly like, share, and subscribe to our post and if it is helpful to you in any way we shall be highly obliged.

Good post.

Thank you very much for reading our blog. We appreciate your words.

wonderful post, very informative. I wonder why the other specialists of this sector do not notice this. You must continue your writing. I am sure, you’ve a great readers’ base already!

Appreciate that you liked our blog. Keep visiting us for more interesting blogs on technical terms.