Gate valve vs. Ball valve: This article will take you through the key differences between gate valve vs. ball valve. Leading industry valve supplier “Hubluxe Engineering” will share the key difference between gate valve vs ball valve, and are ball valves better than gate valves?

Selecting the right valve can make a huge difference between making or breaking your pipeline system. Today we have a huge variety of valves in the market and sourcing the right valve for your desired application can be really difficult.

The most common valves used in domestic as well as industrial applications are Ball valves & Gate valves.

Ball valve operational differences

A ball valve is designed in such a way that it takes a quarter-turn (90 degrees) to open & close the valve completely.

For media isolation where quick closing and the opening are required, there the ball valve is mostly used. It can also be used for slurry application and is also used in tight shut-off is required.

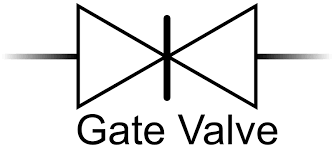

Gate valve operational differences

The gate valve is similar to the ball valve operational structure. Unlike the ball valve, the gate valve has a wedge disc inside that acts as a gate.

This gate in turn controls the flow of fluid inside the valve. It is also known as a slide valve or knife gate valve.

These valves are used in applications where flow is linear and less pressure drop is preferred. Gate valve is part of the rotary family since the wheel or actuator mounted on it needs to be rotated to fully open or close.

Gate valve vs. ball valve key differences

The first thing to keep in mind is that they essentially serve the same function but the key difference is their structural qualities and operation.

| Parameters / Conditions | Gate valve | Ball valve |

|---|---|---|

| Shut-off mechanism | The gate valve requires more than 360 degrees turn to shut off the valve | It requires only a 90-degree turn to close or open the valve |

| Fluid intensity condition | Slow opening & closing of the valve reduce the risk of wear & tear. Even if the intensity of flow is high it throttles the flow. | The fast opening & closing of the valve when the flow intensity is high can cause leakage & sometimes rupture the system |

| Visual detection of valve | It is hard to detect the open or closed state of the valve | The Open & close state can be determined by their handle |

| Required Installation space | Due to its construction, it requires less installation space than a ball valve | It requires more space than a Gate valve due to its quarter-turn handle design |

| Size fitment criteria | Best Suitable for application where bore requirement is above 2” | Best Suitable for application where bore requirement is below 2” |

| Leakage | More prone to leakage than a ball valve | Better shutoff and less leakage |

| Durability | Less durable & prone to damage | Highly durable & less chance of damage |

| Maintenance | Less scope of maintenance & repair | Can be easily maintained and repaired |

| Cost | Typically cheaper than ball valve for similar specs | Tends to be costlier for similar specs of Gate valve |

FAQ